To begin with

Piet Verduijn, 31 years old, lives in Breskens and works as a confectionery wholesaler, delivering sweet goodies in Breskens and surrounding areas for many years.

Full of courage

During World War II, Breskens was badly damaged. There were many losses including Dina, who was Pete's wife. Despite losing his wife, Pete found the courage to move on. In the Havenstraat in Breskens, Pete was seeking for the ultimate sugar wafer recipe to include in his round on bringing the confection. In this region of Zealand-Flanders, the tradition is to bake sugar wafers around New Year.

The entire family helped out

Piet Verduijn travels all over Zealand with his products. The sugar wafers are so well appreciated that the entire family has to participate on selling the products all around Zealand, including his son Adrie.

From home baking to building a factory

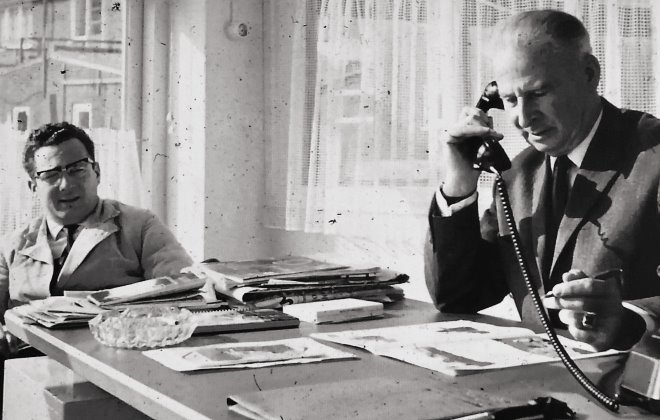

Over the years, the business expanded to countries such as Belgium, France and Germany. The full property has been sacrificed and even the last bit of garden is being used for a new extension. Pete installed a large oven with a packaging line, and had the living room converted into an office. As well, the son-in-law Leo was hired as a pastry specialist. At one point, the house was also known as the "cookie factory" of Breskens.

The transfer of the factory from Piet to his son Adrie

After many successful and busy years, Piet Verduijn handed over the entire business to his son Adrie Verduijn. At that time, the cookie factory had about 35 employees.

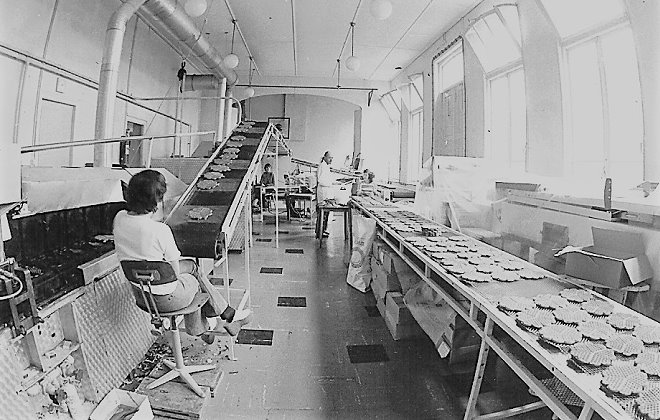

Expansion of the cookie factory in Aardenburg

In the footsteps of the sugar wafer success, new ovens were purchased by Adrie to produce tender wafers. He then bought a property in the former household school in Aardenburg. The tender wafers were well appealed and the production was ramping up. An additional egg cake line was being installed on which numerous delicious products were being baked.

The third generation

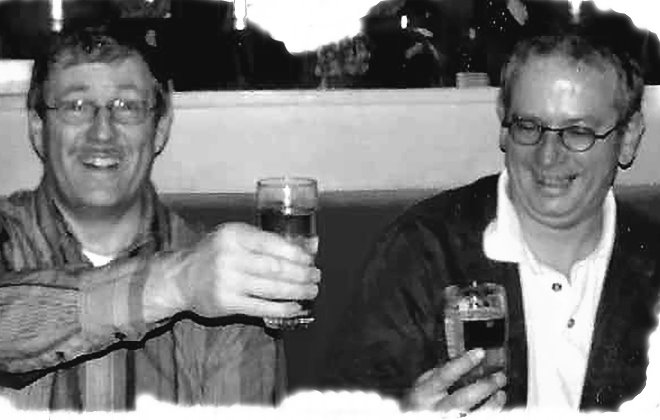

Adrie brought 2 of his 4 sons into the business: Henk and Jean-Pierre. After several years of being involved, a new path was charted. The ovens in Aardenburg were being sold to install new ones in able to produce savory wafers.

Transfer of the business

Adrie handed the business over to his sons Jean-Pierre and Henk Verduijn. The brothers were having big plans such as their grandfather Piet. However, in the beginning, the brothers were struggling with great challenges. With full confidence and the persistence of having high-quality products, things came to a head after 1996. The assortment was growing with new products and new concepts were developed. A new building was under consideration.

A bright future in Eede

As the growth is well in place, the two factories, Aardenburg and Breskens were merged into a brand new factory in Eede. By merging the two factories, the efficiency and processes were increasingly being optimized. With the latest requirements according to the standards of BRC/IFS and HACCP, Verduijn was getting ready for the very future.

New product line

Because of the wafer-thin cookies baked with new techniques, it allows products with nuts, fruit and pieces of chocolate to be well processed. This gives an extra dimension to the assortment of delicate products.

Creation of new cookies

Henk's creativity and passion resulted in several new concepts on the new line. The step by step scaling of products required both patience and persistence. As a result, Verduijn has proudly seen several projects that have paid off and turned into successful cookies.

New packaging equipment

To look steps ahead is to innovate. Since the purchase of new metal detectors, weighing machines and packaging equipment, the production process has been increasingly optimized.

The new look

The packaging also demands innovation. After thorough market research, the old line was modified and this has resulted into very positive feedback. It is not only our business with current customers that has grown, but also lots of new customers are enthusiastically engaging with our products.